BroadReach Construction Machinery Co., Ltd

CAT Fuel Filter 1R-0751

PRODUCT PARAMETERS

| FOB Price: | Contact for Pricing |

| Min. Order: | 10 Unit |

| Brand: | caterpillar |

| Shipping: | Sea freight / Land freight |

Description

Maximize the cleanliness of the engine and engine oil.Meet the expected oil change interval.Provide optimal machine performance and lubrication system protection.Cat®️ filters and fluids are designed as a system to optimize your machine and reduce equipment downtime, thus bringing greater profits to your business.

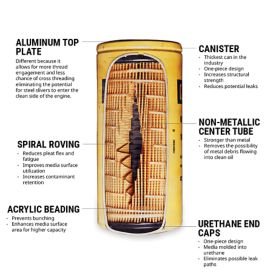

Acrylic Beads to Prevent Wrinkle Collapse • Ordinary filters often experience wrinkle collapse, leading to clogging and shortening the replacement cycle. It can also cause bypass leakage, allowing pollutants to circulate through the system, resulting in additional wear.

• The acrylic bead technology used in Cat®️ filters maintains the rigidity and separation of the pleats, preventing collapse and maintaining maximum surface area throughout the filter’s life. This helps Cat®️ filters capture and retain pollutants until the next replacement cycle. This means fewer oil changes per year, less downtime, and lower ownership and operating costs.

Spiral glass fiber yarns for enhanced pleat stabilityThe spiral glass fiber yarns in Cat® filters eliminate the movement of pleats, ensuring that pollutants are captured and retained. This is particularly important during machine cold starts and shutdowns.In commonly seen filters on the market, pleats often bend, allowing pollutants to pass through the filter medium to the “clean” side, thus causing additional component wear.

Molded End Cap to Prevent Leakage

The molded end cap of Cat® filters completely separates the clean side from the dirty side of the filter.The molded end cap is connected to the aluminum base plate and enclosed together in the integral filter canister. This gives Cat filters greater burst strength and eliminates potential sources of metal contamination.Filters with metal end caps fixed by gluing on top of the filter pleats are prone to leaving gaps, allowing pollutants to re-enter the clean side of the filter.The filter paper of Cat® filters is directly embedded during the formation of the end cap, eliminating potential gaps. During the manufacturing process, the filter paper is embedded before the polyurethane hardens. The resulting bond is extremely strong enough to firmly seal pollutants on the dirty side of the filter.

Central tubeNon-metallic central tube to increase strength and eliminate metal contaminationThe central tube of Cat® filters is made of glass fiber reinforced nylon, avoiding this common source of metal contamination. In addition, the strength of Cat® non-metallic central tubes is 30% higher than that of typical metal tubes, which helps prevent being flattened during pressure peaks and cold starts.Filters with metallic central tubes often carry metal contaminant residues from the manufacturing process. These residues are carried by the clean oil on the clean side and continue to flow through the system, thus causing component wear.

FAQs

All our second-hand excavators undergo rigorous inspections and maintenance before being sold. We provide detailed reports, including operating hours, maintenance history, and condition assessments, ensuring transparency so that buyers understand the machine’s true value and longevity.

We offer flexible shipping solutions to meet global client needs. Our equipment is professionally packaged to prevent damage during transit. We work with experienced logistics partners to ensure timely and secure delivery, and can provide assistance with customs documentation if required.

Yes, we provide comprehensive after-sales support for all our machines. Whether it’s technical assistance, spare parts supply, or general maintenance guidance, our expert team is available to help ensure smooth operation after purchase.

We stock a wide range of international brands, including Caterpillar, Komatsu, Kobelco, Hitachi, SANY, XCMG, and Lovol. Our inventory covers various models and sizes to meet different project requirements, from small-scale to large-scale operations.

Yes, we encourage buyers to inspect the machines either in person or via video call. We can arrange virtual tours where you can view the equipment’s condition in real-time and ask any questions. This ensures full transparency and buyer confidence before the transaction.